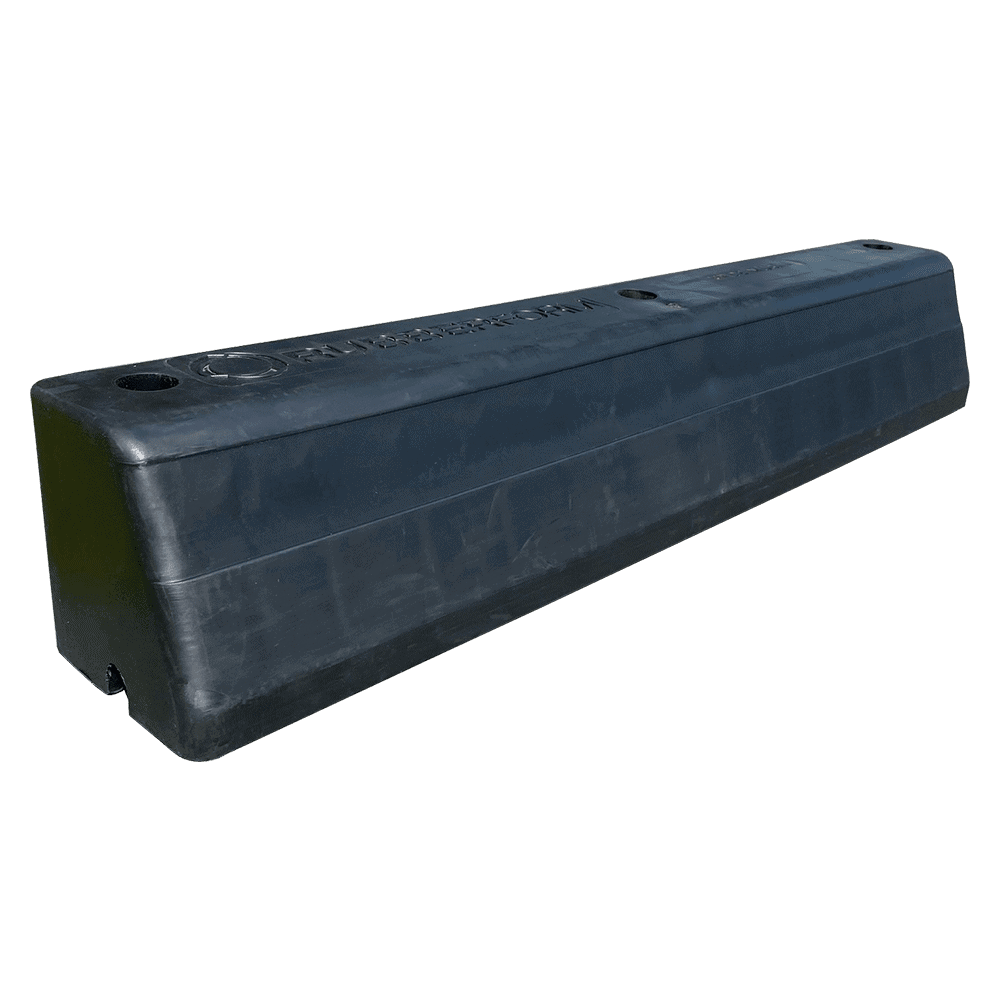

Engineered Trench Guard

RubberForm’s Engineered Trench Guards provide side protection for precast utility trench systems for utility, railroad and public transit companies throughout North America that use these trenches to house electric, cable, and conduit lines, and even pipe, gas, or water lines.

Specifications

- 18 lbs per curb

- 6”H x 6”W x 36’L

- 3 foot sections

- 3 mounting holes per curb

- Color Options: Plain Black or Plain Black with White or Yellow stripe

- Will not chip, crack, crumble, or spall

- Made in the USA with 100% recycled composite material

Product Description

The RubberForm Engineered Trench Guard (ETG) is injection molded with our Next-Gen Recycled Composite Material that combines recycled rubber and plastics that is proven to outlast concrete with hard-wearing durability and low maintenance.

Our utility Trench Guards are engineered to provide side protection for precast utility trenches like Oldcastle’s Plastibeton® cable trench system for utility, railroad and public transit companies throughout North America that use these trenches to house electric, cable, and conduit lines, and even pipe, gas, or water lines.

Each trench guard section can be spiked with rebar into gravel or dirt surfaces, or lag bolted into asphalt or concrete along with dual flange connectors that hold it in place. ETG’s can be fabricated to be installed to your specific length requirements.

RubberForm’s ETG is used where snowplows or traffic travel across these precast utility trenches where breakage would be costly and devastating to the utility grid. The ETG will take impact before the trench system and protect the enclosed trench from damage. The ETG has been used for years in the Northeast and is specified for several electric utilities on various substation projects.

Models

RF-ETC36

- Engineered Trench Guard – All black (preferred choice)

- 18 lbs per trench guard

- 6”H x 6”W x 36”L

- 3 foot sections

- 3 mounting holes per trench guard

RF-ETC36R-YLW

- Engineered Trench Guard – With yellow reflective stripe

- 18 lbs per trench guard

- 6”H x 6”W x 36”L

- 3 foot sections

- 3 mounting holes per trench guard

RF-ETC36R-WHT

- Engineered Trench Guard – With white reflective stripe

- 18 lbs per trench guard

- 6”H x 6”W x 36”L

- 3 foot sections

- 3 mounting holes per trench guard

Hardware Kits

RF-ETC36HWK

- 3 – 1/2” x 10” Lag Bolts

- 3 – 1/2” x 1-1/8” Washer

- 3 – 1/2” x 3” Anchors

- 3 Black Rubber Caps

- 1 Dual Flange Connector

RF-RBR (For installation on dirt or gravel)

- 14”, 18”, 24”, or 36” long galvanized rebar spikes with cap head

Key Features

- Easy to install, remove, and replace

- Can be installed on gravel, asphalt, concrete, or prepared surface

- Extremely durable

- Resistant to temperature, UV light, oils/fuels, salts, and moisture

- Will not chip, crack, crumble, or spall

- Color Options: Plain Black or Plain Black with White or Yellow stripe

- Made in the USA with 100% recycled composite material

100% Recycled Materials

Manufactured with only post-consumer or post-industrial materials.