Key Takeaways

- Portable sign bases solve the biggest signage problem: mobility, letting you easily relocate signs as traffic or parking needs change.

- RubberForm solid and fillable bases are lightweight enough for one person to move, yet stable and wind-resistant due to low center of gravity.

- Solid bases are more durable and long-lasting; fillable bases are cheaper but can fail if cracked or damaged.

- Installation is simple: pound in the post, attach the sign, tip and roll into place—no heavy lifting or demolition required.

- Made in the USA from 100% recycled materials, these bases are built to last, sustainable, and compatible with a wide range of signposts and applications.

Good signage can be the difference between an incredible customer experience and a lousy one. Poorly placed and even straight-up incorrect signage can be disastrous for a business or municipality. The vast majority of signage problems comes down to one thing: portability.

Parking lot and street traffic needs are always changing. It’s hard to predict long in advance where exactly a particular sign should go for best visibility and traffic flow. With portable signs, you don’t have to.

The old way of doing things

Traditional signage is installed directly into asphalt or poured concrete. That means no changes to angle or placement of a sign after installation. If you do need to change something, it requires demolition and repouring of concrete just to remove and reposition one sign. That’s why sometimes see a lone sign post sticking up out of a parking lot without a sign attached–they needed to make a change and didn’t want to demolish it!

One way contractors have tried to solve the mobility problem is with concrete sign bases. They are technically mobile, but are extremely heavy: 200-300 lbs and more. That means they require multiple workers or special equipment to carry.

The concrete bases are lifeless and ugly, and it’s only going to get worse. They will chip, crack, and crumble in the heat, in the cold, if they tip over, and if any vehicle collides with them. And that means that before long, you’ll need to replace them.

The new alternative

Rubber and plastic sign bases are two viable alternatives to permanent asphalt or concrete sign installation or heavy concrete sign bases. Each has its advantages.

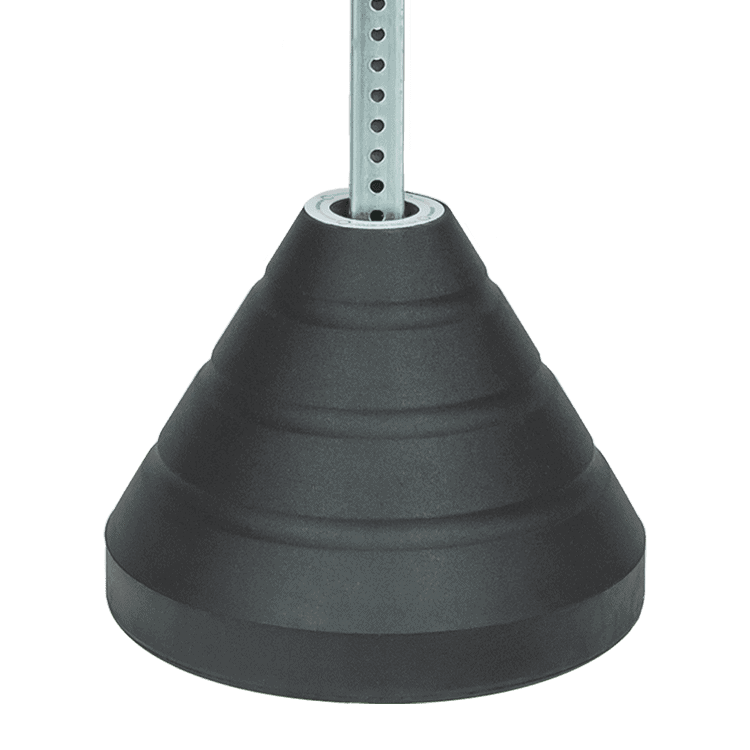

Solid sign bases are usually made of rubber. Our RubberForm Portable Sign Bases are made from a special recycled rubber and plastic composite material. They are heavy enough (72 lbs) to stay put where you leave them, but light enough to be movable by a single person when needed.

Plastic sign bases are hollow shells intended to be filled with a heavy material to weigh them down. Water, sand, and gravel are all common fill materials, though water is dangerous to use in areas that can freeze. Our RubberForm Portable Fillable Sign Bases come with a special gel that won’t freeze at low temperatures for precisely that reason.

How do I choose between solid vs fillable?

Solid sign bases are generally tougher and will last longer. The main advantage of fillable sign bases is their cheaper price.

Our solid and fillable sign bases are both wind resistant due to their weight and a low center of gravity. They’re both highly portable too. Our solid sign bases can be tipped on their side and rolled easily by a single person. Our fillable sign bases have built-in wheels for easy portability.

A solid base will be more durable against chipping or cracking than a fillable one. If you do manage to damage the base, it will likely still function well. A fillable base that has cracked or crumbled will leak its filling and quickly become unusable.

So budget and durability are the two most important factors in choosing solid vs. fillable.

What makes RubberForm sign bases different?

Our solid sign bases are made from a special 100% recycled rubber and plastic composite material. Our fillable sign bases are made from 100% recycled plastic. Both are tough and long-lasting: no chipping, no cracking, no crumbling, no corroding, no matter the searing heat, the freezing cold, or heavy use.

Both varieties of sign base are wind resistant with a low center of gravity. If you need to use signs in an especially high wind area, you can add on a base weight to our solid sign base that brings the total weight up to 150 lbs.

How easy are your signs to use?

RubberForm portable sign bases are the simplest way to great signage. Installation is so easy your grandparents could do it (if you hired them to). All you need to do is pound in your sign post, attach your sign, then tip and roll the base into position. It’s that easy.

Sign base installation:

- Pound in sign post

- Attach sign

- Tip sign base + post over

- Roll into position

When you need to relocate, tip and roll again.

Many competing sign bases are square or octagonal, meaning they must be carried or transported by some other means, but our round design rolls easily. They’re heavy enough to stay in place, but light enough for a worker to tip over for rolling.

Installation is so simple that you could use our sign bases for a quick-deploy process like curbside pickup that is only available certain times of the day or special event parking and traffic flow.

RubberForm Sign Bases:

- Easy installation, removal, and relocation

- Won’t chip, crack, crumble, or corrode

- Low center of gravity for wind resistance

Do you have other ways of improving my parking lot?

RubberForm is a one-stop parking lot shop, what we call a 360⁰ solution. Every product is as easy-to-use, durable, and long-lasting as our portable sign bases.

If you like our sign bases, you’ll love our portable bollard bases for high visibility vehicle impediments. Our shopping cart corral bumps keep shopping carts safely in their corral, but allow your customers to easily pull them out. For temporary traffic calming, you can lay out our MLSB speed bump in minutes and collect it back up just as easily. You could also anchor it or use one of our other speed bumps, speed humps, or speed cushions for permanent traffic calming.

And if you love the look of our sign bases, take a gander at our fully brandable wheel stops. You can use our stock colors to color code handicap, emergency, and EV charging spots, or have us custom print your own colors, your logo, or both!

Made in America

Every one of our portable sign bases (and the fillable variety) are made right here at our factory in Lockport, NY. We do all our own design and engineering here too, because we believe in American ingenuity and hardworking American hands.

We also source all our recycled materials domestically, typically from within 500-1000 miles of our factory. This means with every purchase you’re helping us clean up America’s backyard. Because every ton of recycled material we use is a ton that was kept out of a dump or landfill.

Ready for the simplest signage imaginable?

One step toward an incredible customer experience (that starts before they even park) is flexible, effective, high visibility signage. RubberForm’s portable sign bases take the guesswork and heavy lifting out of signage placement. They look so much better than concrete or asphalt, are more durable, and most importantly are so easy to relocate as needed. Our recycled rubber and plastic composite is engineered to never chip, crack, crumble, or corrode, so you can use our sign bases for years and years to come. Upgrade your parking lot with the simplest sustainable signage on planet earth.

Send us a message or give us a call to get started!